With the steady growth of the world economy, consumer demands of toy products are increasing rapidly. Based on the original intention of health and safety, countries or regions around the world have established strict standards for toy control, and constantly updated and refined. Toy safety problems are constantly happening and the relevant laws and regulations of the sanctions are increasingly severe,which bring great challenges to toy manufacturers, importers and retailers.In order to ensure the safety of toys, different areas have different safety standards,in which European standards is considered as a wider range of applications, it needs to pass the strict EN standard testing,no exception for toys. Several of the most commonly used toy safety test are: torque test, drop test, impact test, Compression Test.

(First Part)

Torque Test: Torque test steps: apply clockwise torque force on the component in 5 seconds , twist to 180 ° or 0.34Nm, hold for 10 seconds and then return the parts to the relaxed state, counterclockwise repeat above process. Less than or equal to 6 mm, a force of 50 N + 2N is applied, and if the size of the maximum protruding part is larger than 6 mm, a force of 90 N + 2N is applied.Put on pounds in 5 seconds and keep for 10 seconds.

Judgment criteria: toys designed for small children who can’t sit up alone should not be cracked,if the crack does not cause damage obviously,it is acceptable.Toys designed for children under 3 years should not produce small parts, contactable sharp point and sharp edge. Masks and helmets should not have exposed cusps, edges, or loose materials that can enter the eye. Oral toys and toys used in the water should not produce small parts.

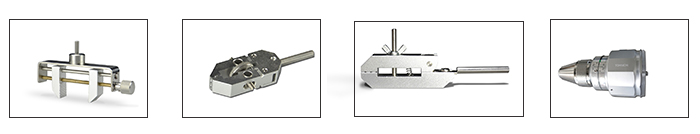

Equipment: Large Torque Fixture, Middle Torque Fixture, Small Torque Fixture, Torque Gauge

Standards: ISO 8124-1, GB 6675-2, EN71-1, ASTM F963, 16CFR 1500

留言列表

留言列表